- Home

- Principles and Practices

- Computer Aided Design

- Computer Controlled Cutting

- Electronics Production

- 3D Scanning and Printing

- Electronics Design

- Molding and Casting

- Embedded Programming

- Computer Controlled Machining

- Input Devices

- Composites

- Interface and Application Programming

- Output Devices

- Networking and Communication

- Mechanical/Machine Design

- Applications and Implications

- Invention, Intellectual Property, and Income

- Project Development -- Final Project

| 1. The first question I have to answer is pertaining to how my piece of the machine will connect with the rest of the pieces. I am creating the slider tray and it will have to hold

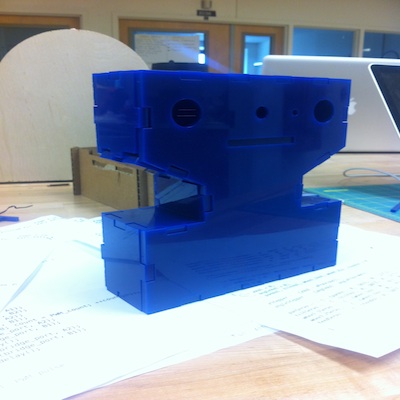

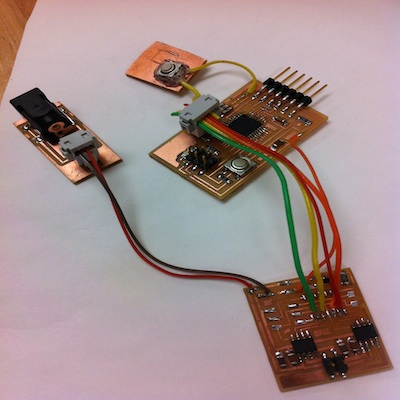

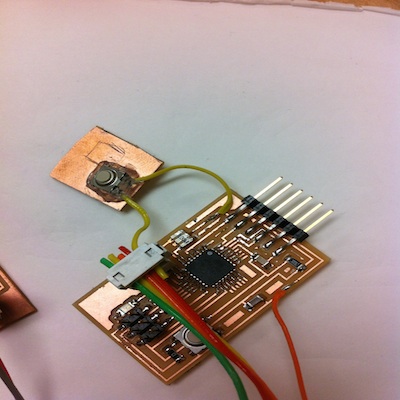

almost the entire ping pong machine. I will resolve that issue by simply cutting a small hole for a screw that will connect my tray plate to the pan and tilt mechanism that my piece will connect directly to. 2. From this point on I can improve on the mechanics of my machine. I used a lead screw to move my slider tray; however, I did not take into account the top speed of the motor matched with the lead screw. My programming code also needs more work. Looking at it, I am sure that a more experienced program could tell that I am novice. 3. After multiple attempts, The code is functional and I have gotten my part of the machine to slide both left and right across the width of the table. The frame is solid and I has the capability of holding up to 30 lbs.  4. I plan on continuously making improvements and adjustments well past the MIT Fab Academy cut off date. This project has improved on my understanding of motors, the programming of motors and different materials that can hold and be attached to these motors.... I was able to improve on my CAD techniques as well. 5. This machine in its entirety would take me a month to complete on my own. The demand for a unique table tennis training machine would always be there (my opinion) but for in order to reach that demand I would have to improve on my overall fabrication skills. My part of the project took longer than I expected. The mechanics and design part of my machine came to me much easier than the programming did. I spent most of my time attempting to originate my own Stepper motor code. My experience with this project allowed me to understand my work pace as well as realize my strengths and weaknesses. My strengths came with designing it:  I found much of my inspiration for this design from the press fit techniques learned throughout this course. I first planned to create a composite of wood and linen for the casings but acrylic simply looked much better. My machine has the capability of sliding the width of the ping pong table. While the machine is moving across the table (at a turtles pace) the ball launcher program will be activated so that the table tennis player being trained will be able to return various speed serves from all positions on the table. My program code can be found at this link: Please feel free to drop me a line and let me know what I could have done better. I made my own arduino board and added another switch to it, connected my stepper motor board to it, and finally I soldered a power supply adapter to the arduino board. As a result, I have created a network of boards that have the capability to communicate to each other as well as communicate to the Arduino Serial Port.   At first, I looked at the speed of my slider as a problem until the idea to make it a feature came to me. Links to my tray design can be found here: The circuit boards will be placed inside of the side casings. I had them outside of the casing while I continue to edit the code to make the motor execute more advance tasks. This project was a great start for me. Although I did not do as great as I wanted to with this project, I feel that the experience was far greater than anything else. I have the motivation to swim out deeper into the still waters of programming and digital fabrication. I now aspire to build more and to learn more for the betterment of the future. |